| I had quite an assembly team building the ribs. The entire family pitched in and we had all of the

wing ribs done in 2 days! |

|

| Lots of completed wing ribs laying out to dry! |

|

| Close-up of the joints on a rib. |

|

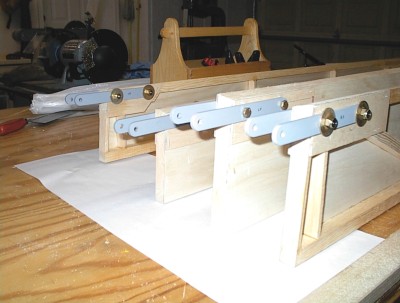

| Completed Wing Spars. The hardware is being trial fit. Yes I am building my own hardware and not

using the pre built kit option. |

|

| Here are the wing spars ready for wing assembly. |

|

| This is the strut attach point on the spars. |

|

| Finally the first wing panel laid out and glued up. Notice the compression struts and drag members

being installed. |

|

| Another view of the wing panel. |

|

| Here are the compression members that keep the spars separated in flight! |

|

| Aileron cross bracing structure. Notice how it attaches to both the top and bottom of the aileron

spar. |

|

| Here is the Bracing from the other side after the nose sheeting is attached to the Aileron. |

|

| Wouldn't it be nice if the parts came dicut ready to use like this? Ok I guess it would make the

kit cost twice what it does now, but what a load of work to fabricate all these parts. |

|

| Now it's time to prepare the leading edge sheeting for attachment. Notice

it has been formed in the jig already. Here I have masked the glue lines and varnished the rest. |

|

| Look at that beautiful curved nose rib and sheeting! That jig really paid off here. |

|

| Here you can see the varnished interior structure before sheeting the box in. Also make sure to

attach the wing hold down strap before closing it into the LE. |

|

| Nice clean joints with very little gap or irregularity between the pannels. (even I was supprised!) |

|

| Finally the finished product! Now I just have to pull about 300 staples! |

|

| Here is a view of the root end of the left wing. After gluing on the skins, but before pulling the

staples. |

|

| After cutting off the Aileron you attach the wing trailing edge. This is what the fabric attaches

to at the end of the wing before the Ailerons. |

|

| I ended up using a block plane to put the 45 deg bevel on the trailing edge strips. It worked best

to do it before gluing them on. |

|

| The Aileron sheeting is installed much the same as the wing. It is nice that it is thinner plywood,

but it is harder to position since it is so small. I built a jig to form the plywood just like the wing nose section. |

|